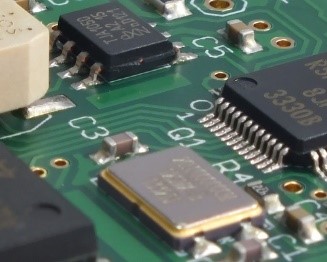

Smd Assembly Service - processes and facilities

Profiants is your competent partner in the SMD assembly

- Reflow soldering

- ROHS compliant manufacturing

- Automatic SMD assembly

- Manual SMD assembly (prototypes and small series)

- BGA's

- Finepitch

- 0402

- 0201

Assembly capacity:

- up to 100.000 components pro hour

- up to 3.500 pro hour for Fine-Pitch

The SMD production process chain in 3 easy steps:

1. First the soldering paste is applied to the SMD pads

2. Then the components are placed using SMD machine

3. Finally everything goes through the reflow oven.

2. Then the components are placed using SMD machine

3. Finally everything goes through the reflow oven.

1. Solder paste and solder paste printing

Stencil with a thickness of 100 µm, 120µm or 150 µm is created.

Durring the process solder paste printing, the solder paste is applied through a stencil holes.

Printing is done with a solder paste printer. The printer has the function of vertical detachment of the printed circuit board.

This guarantees that the shape and volume of the paste remain constant.

ROHS or lead-containing ?

- Lead-free and lead-containing solder paste could be used.

Since most components are RoHs compliant, we recommend using lead-free to avoid the problems of heterogeneous coatings.

We use solder paste Warton Metals

- Warton Metals

- Microprint P2010

- SAC305 88.0 25-45

-

No clean solder paste

- Corresponds to IPC 650

2.Assembly

The assembly of the SMD components takes place with assembly machines.

Compared to machine assembly, we offer manual assembly for prototypes and small quantities, which meets high quality standards.

The quality is the same as in series production.

Please note:

Components should be drawn in such a way that their 0-point is in the middle of the package body!

3.Soldering

After the assembly process, the printed and SMD-assembled circuit board is soldered using the reflow soldering process.

reflow oven (conventional) with conveyor belts is used for soldering.

The entire assembly is exposed to a fixed temperature profile (soldering profile).

The previously viscous soldering paste melts into solder and thus permanently connects the applied components with the connections on the circuit board.

Very Important!!

This is by no means the case!!

During reflow soldering, components briefly float on a layer of liquid tin and follow the surface forces.

The pad design and the quality of the solder paste print must ensure that the components do not move unintentionally in this state.

It is not for nothing that it is said that approx. 50% of soldering defects are caused by stencil printing.

In the area of SMD assembly, we have three complete lines at our disposal

Line 1

(3000 comp. per hour)

- Printer (DEK 248)

- Pick&Place (Juki 570)

- Reflowoven (SMT-Wertheim)

- AOI System (Marantz)

Line 2

(12-15.000 comp. per hour)

- Printer (DEK 248)

- Handling system

- Pick&Place (Juki 2060)

- Reflowoven (Seho)

- AOI System (Marantz)

Line 3

(60-80.000 comp. per hour)

- Printer (DEK Horizon)

- Handling system

- Pick&Place (Juki FX-3L und KE-3020L)

- Reflowoven (Seho)

- AOI System (Marantz)

Sample production

In certain situations, for economic reasons,

it makes sense to place individual SMD components by hand or even to assemble individual assemblies completely manually.

For example, in the case of non-recurring patterns in small quantities and low complexity of the SMD assembly,

a complete program creation and setting up of the assembly line can be too expensive.