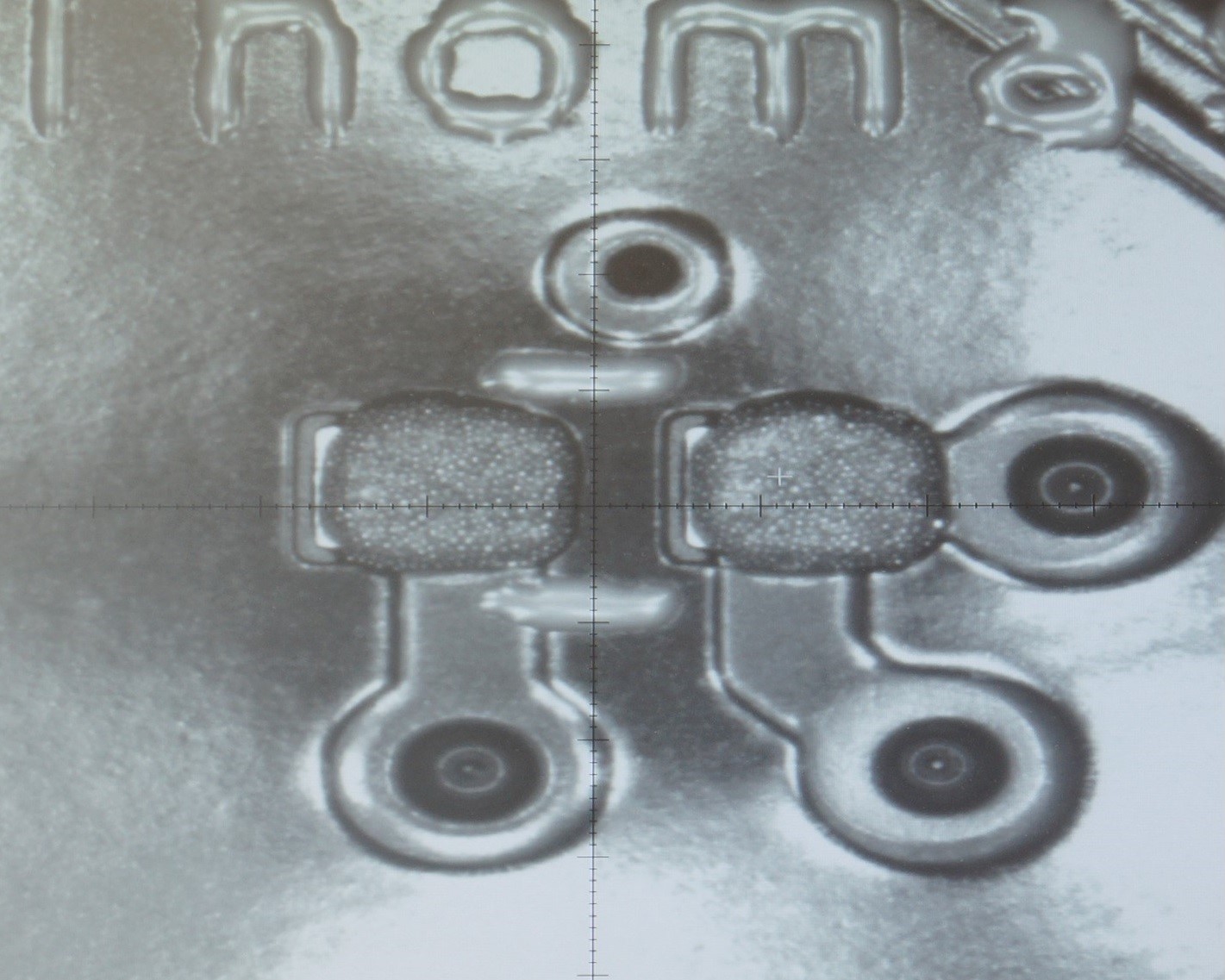

Solder Paste Stencil

Solder Paste Stencils

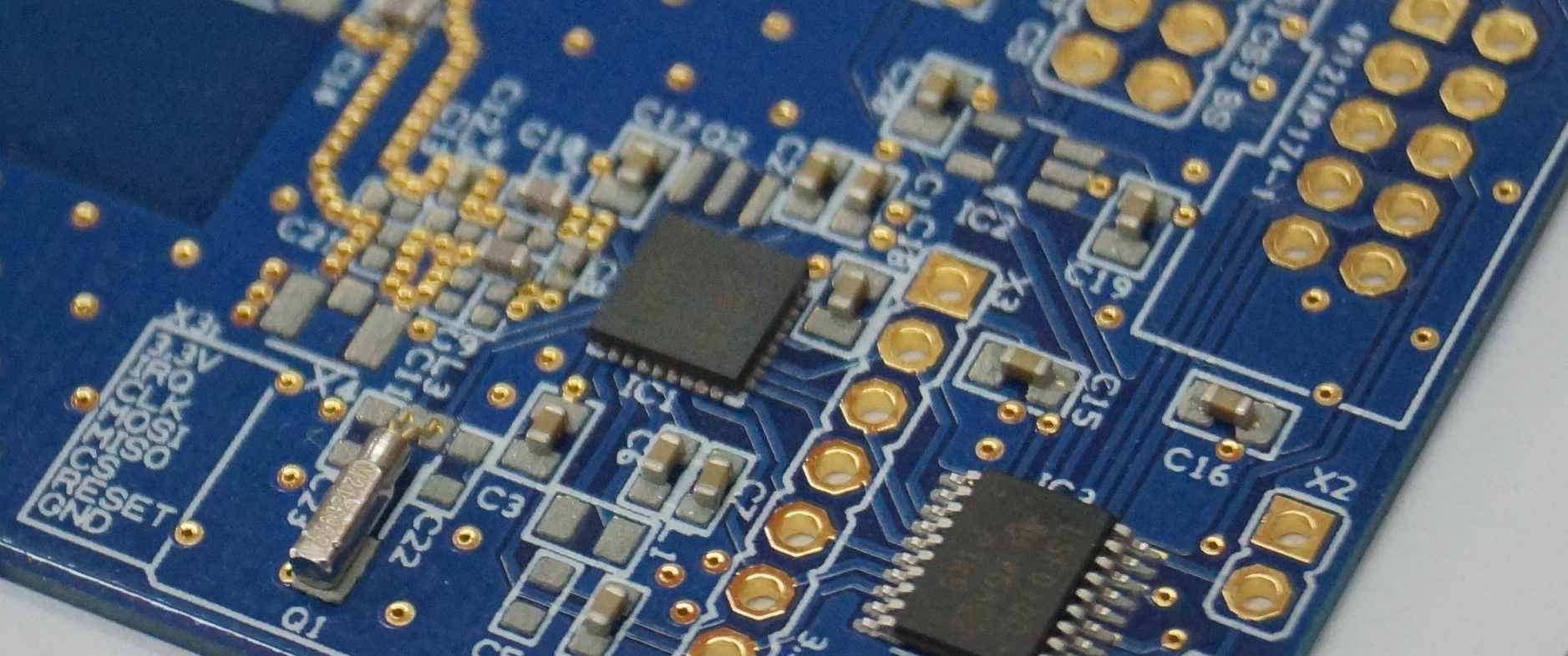

Solder Paste Stencils are critical to PCB assembly. The first step in the assembly process is the accurate deposition of solder paste.

We offer of a large selection of stencils cut with laser, etched or mechanically.

Our stencils are made from new silver/copper-nikel-silver alloy or stainless steel. Etched stencils are perfect for low-volume usage prototyping.

We recommend etches copper-nikel-silver alloy for the ultimate in quality and precision solder paste applications.

LASER CUT PROCESS

| Lead time: | 1-3 Days |

|---|---|

| Material: | nickel silver |

| Max size: | 600x600mm |

| Thickness: | 100um, 120um, 150um |

| Smallest aperture size: | 2mils / 0.05mm |

| Pads: | unlimited |

| Text characters : | Free of charge |

| Final treatment: | double-sided brushing |

CHEMICAL ETCHING PROCESS

| Lead time: | 1-3 Days |

|---|---|

| Material: | nickel silver |

| Max size: | 600x800mm |

| Thickness: | 100um, 150um |

| Smallest aperture size: | 4mils / 0.1mm |

| Pads: | unlimited |

| Text characters : | Free of charge |

| Final treatment: | double-sided brushing |

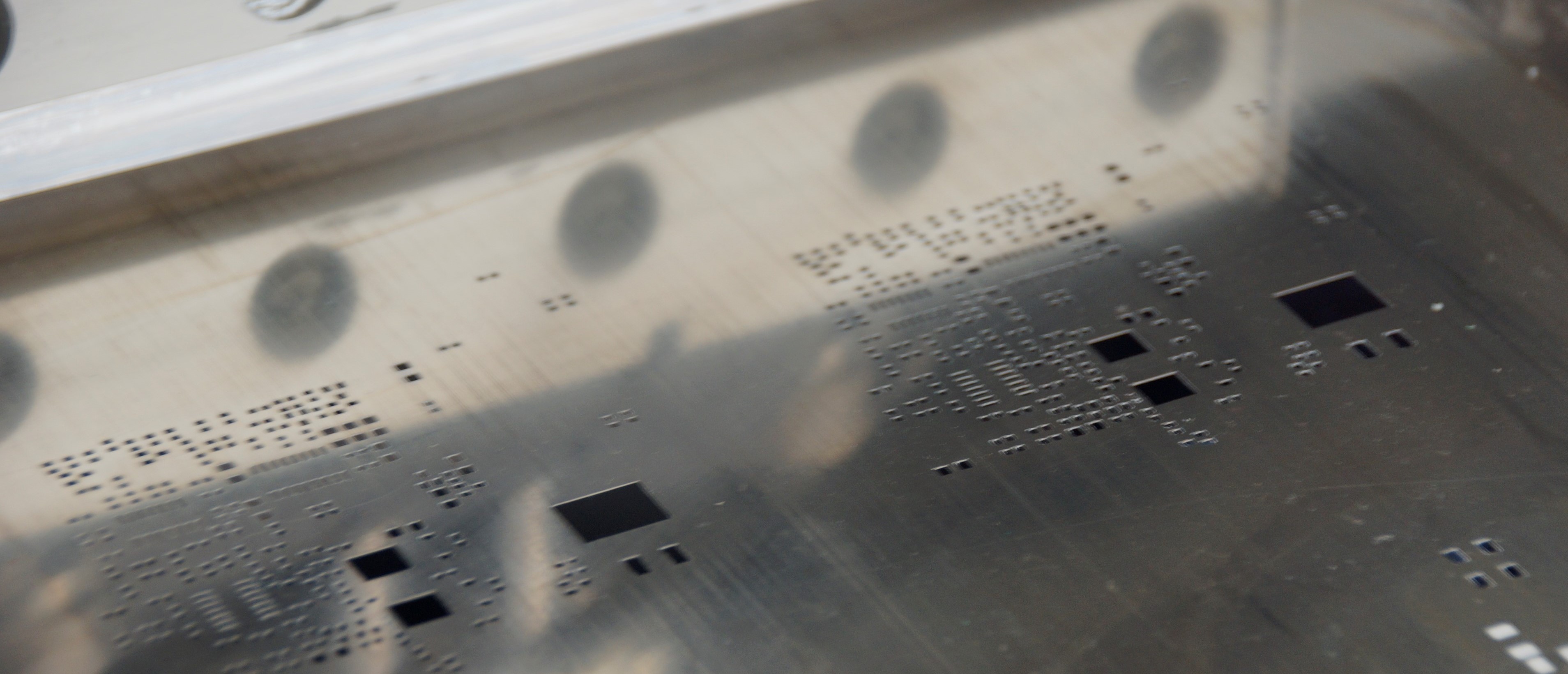

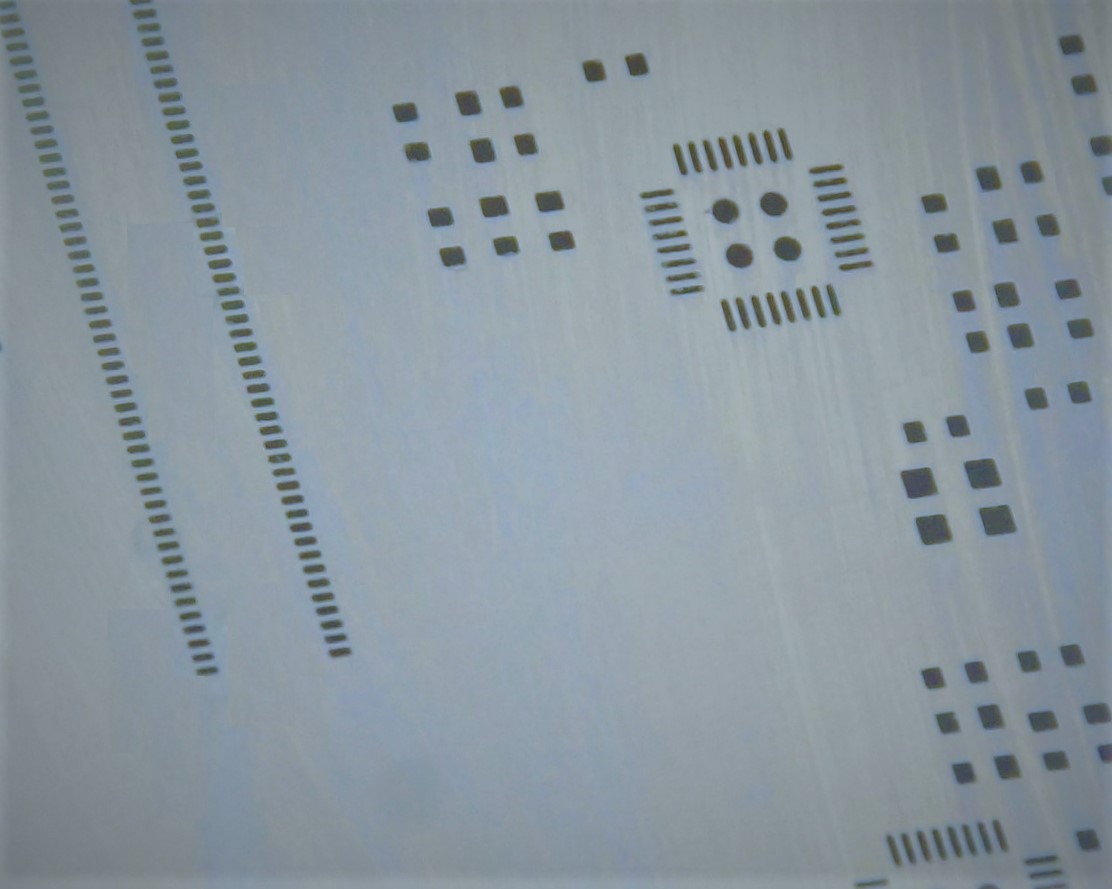

Chemical etching

Chemical etching is a process used to remove material (metal) by way of masking an area with a protectant (photo resist)

and then submerging the material into an etchant (acid) to remove the material that has not been protected by the photo resist.

It is an extremely precise and cost-effective process that facilitates the production of a wide range of burr and stress free parts and tools in virtually any metal.

Why use Chemical etching?

Base material stability:

Chemical machining does not change the properties of the material being etched.

Where as processes like laser cutting can produce a heat affected zone which can cause expansion and contraction;

chemical etching will not change material temper or hardness during processing.

Prototype compatibility:

Design changes are simple and quick to implement.

Much like laser cutting this is especially suitable for prototype builds but is more efficient than laser cutting for production.

Etching service

We offer a fully capable chemical etching service.

From the simplest to the most challenging projects we are your solution for prototype and production runs.

Our chemical etching solutions are creative, competitively priced, and focused on the customers needs.

Materials

A wide range of materials are suitable for chemical etching. Most metal alloys can be machined with this process.

Some examples are various Coppers, Brass, Nickel, Stainless Steel, Kovar, Spring steel, Invar, Monel and more.

Prototype compatibility

Chemical etching is a process used to remove material (metal) by way of masking an area with a protectant (photo resist)

and then submerging the material into an etchant (acid) to remove the material that has not been protected by the photo resist.

It is an extremely precise and cost-effective process that facilitates the production of a wide range of burr and stress free parts and tools in virtually any metal.

Pricing

Small

15€

-

• Size: 100x120mm (1.2 dm2)

-

• Thickness: 100um

-

• Material: nickel silver

-

• Lead time: 3WD

-

• PROCESS: chemical etched

Medium

25€

-

• Size: 150x200mm (3 dm2)

-

• Thickness: 100um

-

• Material: nickel silver

-

• Lead time: 3WD

-

• PROCESS: chemical etched

Big

30€

-

• Size: 200x200mm (4 dm2)

-

• Thickness: 100um

-

• Material: nickel silver

-

• Lead time: 3WD

-

• PROCESS: chemical etched